Efficient factory and production planning

Systematic and goal-oriented processes in your production.

Factory planning and optimization throughout the entire planning process up to factory commissioning

Do you want to design your production and logistics in a process-oriented manner and exploit the potential through optimal structures?

The requirements for modern factories are diverse and pose major challenges for industrial companies. The key to the sustainable economic success of a factory lies in the planning phase, long before production begins.

SME SCHMID realizes your factory planning according to overriding main objectives:

- Efficient production and manufacturing flow

- Attractive working environment

- Good utilization of space and area

- Great flexibility of buildings, facilities and equipment

Competence in modern factory and production planning worldwide

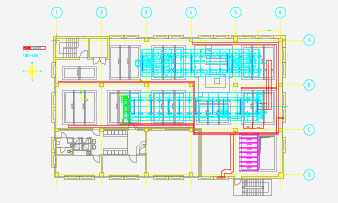

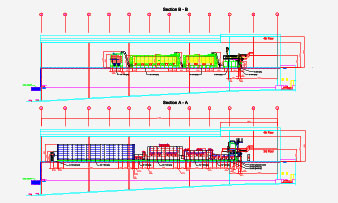

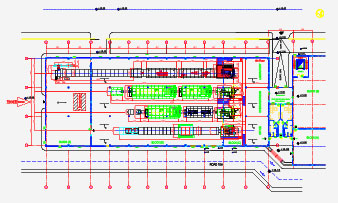

Here, the project spectrum ranges from the replanning of individual subareas to the general planning of entire manufacturing systems. We undertake layout planning in 2D and 3D. During planning, the spatial situation is taken into account, but the entire production process is also planned and optimized.

- Project planning

- Production flow planning

- Layout creation in 2D / 3D

- Assembly layout / floor loading plan,…

- Adaptation of heating schemes, cooling schemes,…

System planning

3D model with 3D printing for more imagination

Physical 3D models are an optimal complement to your plans and virtual 3D models. The plastic processing makes it much easier to visually illustrate the production processes.

Advantages of 3D printed models:

Speed, shape and color are significant advantages. The former not only saves you time, but also cash. The latter give you freedom in design – from complex structures to small full-color details.

Simplify planning

Even in early planning phases, you can compare, assess and optimize your designs. This helps to avoid costly planning errors. Another point for avoiding errors is the high precision of the model, which can thus also simplify decision-making and coordination processes.