News

Successful trade fair participation: SME-Schmid at the IPACK IMA 2025

Successful trade fair participation: SME-Schmid at the IPACK IMA 2025 Thank you for your visit - a strong sign of innovation and

Dough preparation for fresh spaetzle

Dough preparation for fresh spaetzle For perfect spaetzle or knöpfle, the dough must be whipped smooth, firm but slightly runny. This requirement

KELPA goes Schmid

KELPA goes Schmid Kellermeier Maschinen und Produktionsanlagen: Takeover of service and production Since 1982, we have specialized in the worldwide procurement, relocation

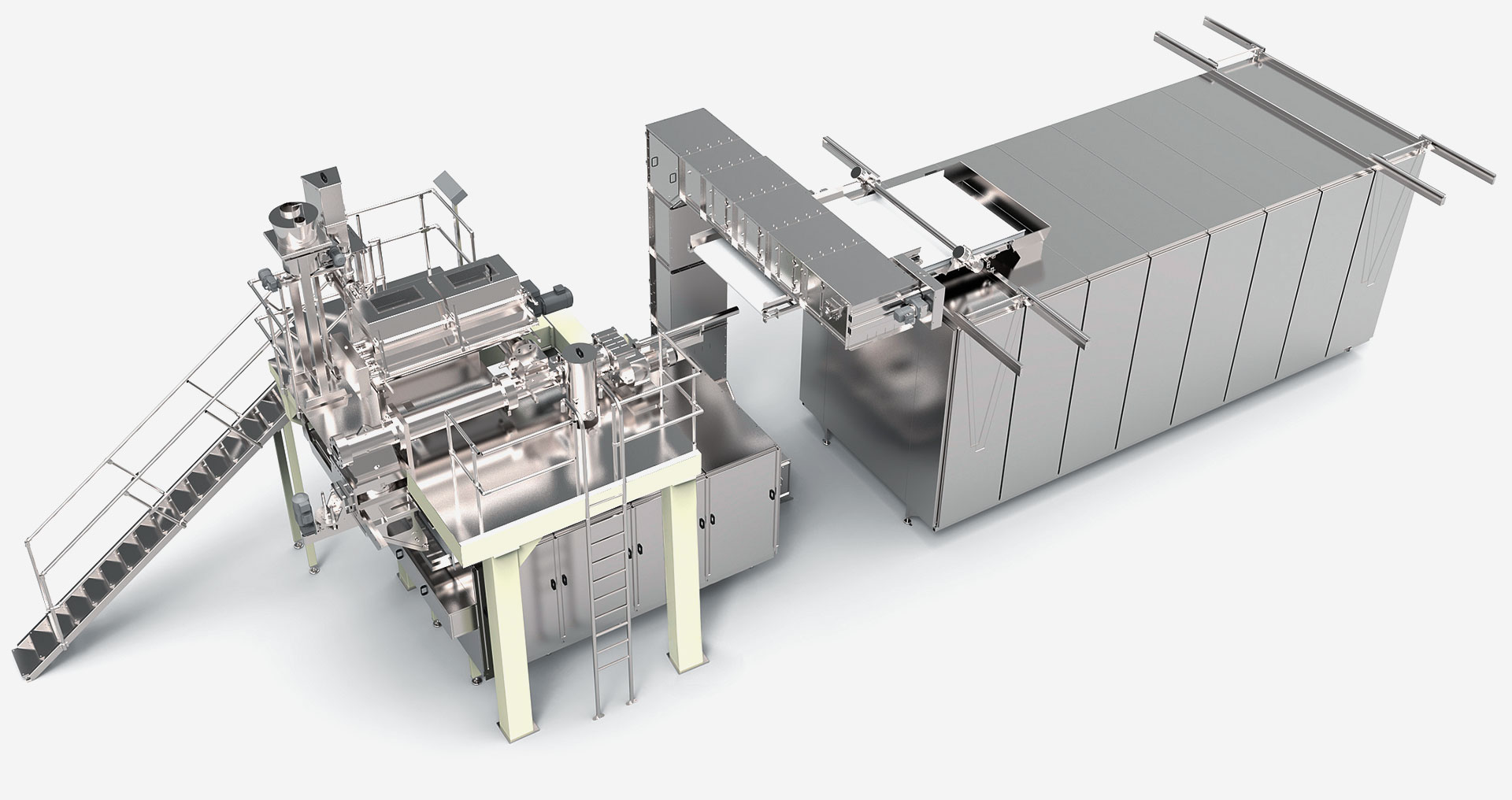

Pasta production

SME SCHMID designs and manufactures machines and complete lines for the production of pasta such as penne, fusilli, croissants, croissants, spirals, ribbon noodles, ravioli or even spaetzle with 250 to 3,000 kg/hour. Our machines and systems can be optimally adapted to your operational and economic needs.

Used machines

New life for old but reliable machines

SME SCHMID brings together supply and demand for used pasta machines and pasta plants. We have 35 years of experience in procurement, design, and relocation through to turnkey plant installation.

Why not buy a used plant? Used machines and components immediately available.

Service for your machines

With the SME SCHMID service, you increase the productivity of your pasta machines and pasta plants and reduce costs by minimizing expensive downtimes and repairs. In the process, you extend the service life of your machines.

Should a repair be necessary, highly qualified service technicians from SME SCHMID are there for you – in person on site or via remote support.